Optimal Solutions

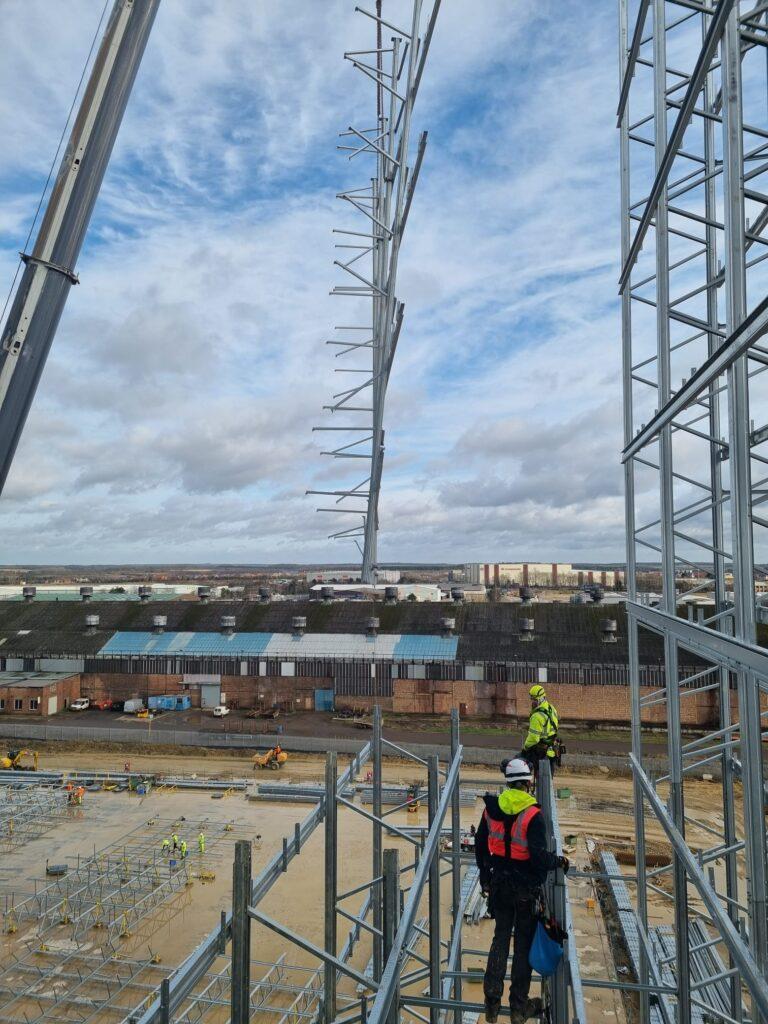

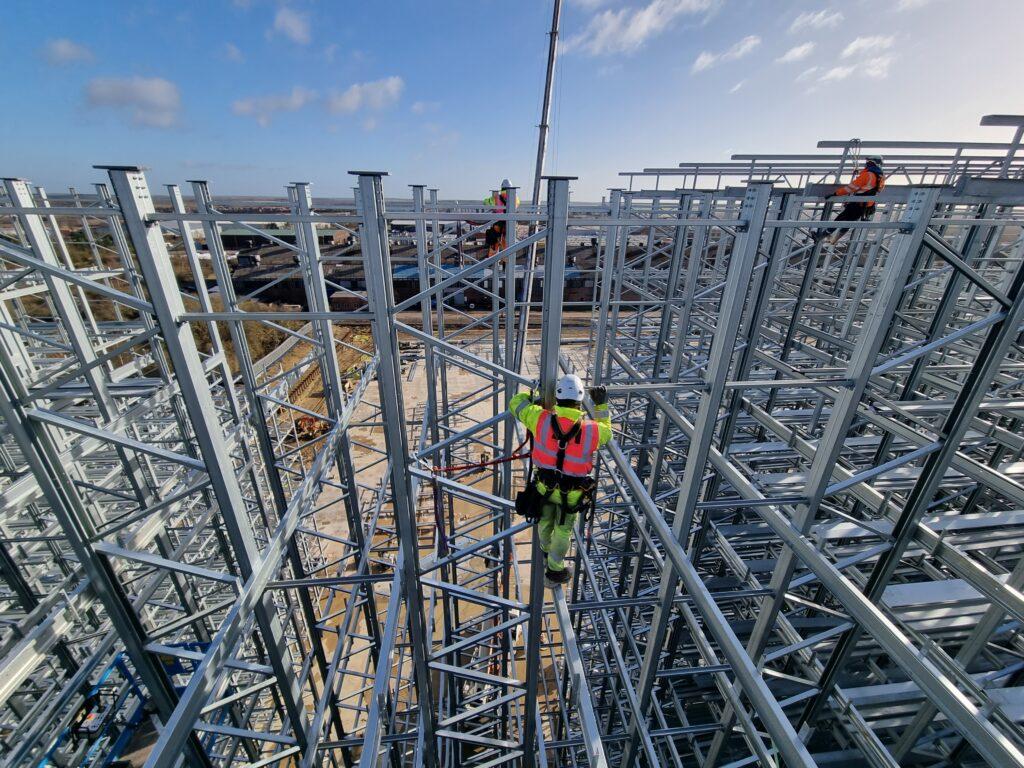

“Our excellent performance in constructing high bay warehouses, and the way that our team expertly co-ordinate ground preparation and block assembly with our aerial team, is the reason that customers come directly to us carry out their projects.”