KEY THINGS THAT GO WRONG WITH CLAD RACK WAREHOUSE PROJECTS AND HOW THEY CAN BE FIXED.

Delays in time schedule

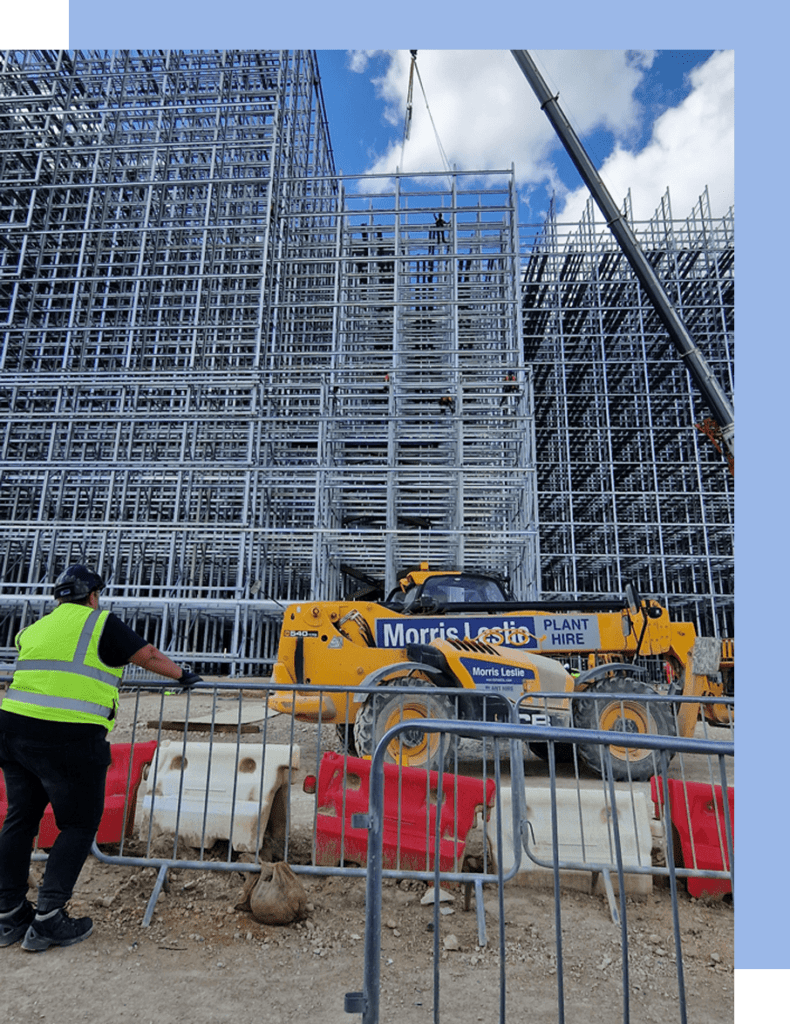

Some very large high bay projects are scheduled to run for 6 to 12 months and that is a lot of time for things to go wrong. Though expensive and annoying, delays are something that all contractors and clients should be fully prepared for and focused on minimising.

It is a sad statistic but often quoted, that only 10% of international construction projects are actually completed on or before the specified deadline. Ouch! To make it sound even worse, that means that 90% of projects are expected to be delivered late which can also lead to financial loss and serious penalties.

There are many reasons for construction project delays, but more often than not, the delays are caused by a combination of budget inaccuracies, delays with permits, labour shortages, poor weather and a simple lack of thinking and planning ahead on the site including site preparation, lost or missing components, lack of preparation of work areas and a back-up plan to utilise the workers while they cannot perform their scheduled activities. Whilst most delays cannot be anticipated accurately, it is certainly possible to incorporate their probability into the time schedule.

It is not enough to just add a fixed percentage onto the budget and hope that will cover all eventualities. Careful thought should be put into what is likely to happen, how that likelihood can be mitigated and what the cost will be in the worst case scenario in terms of time and money.

Lack of Skilled Workers

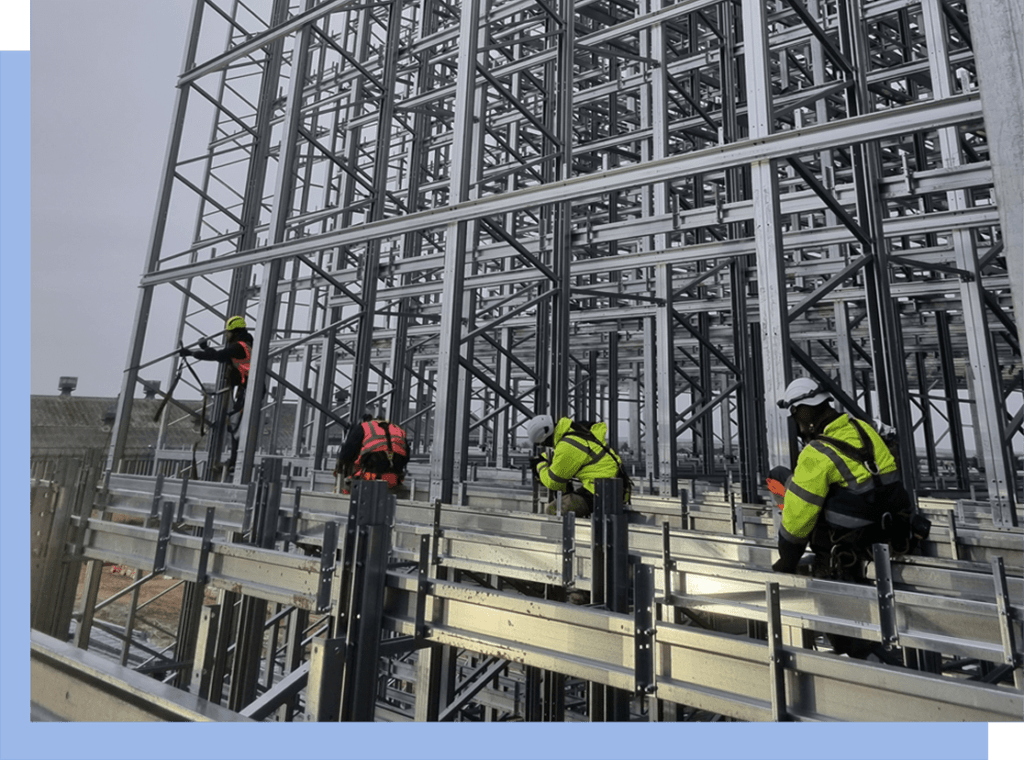

There has always been an issue facing the high bay / clad rack warehouse and logistics centre construction industry: not enough skilled workers to keep up with rapidly growing demand. Younger generation are increasingly moving toward college, and not vocational trades. The benefits of a career in construction are not being explained to millennials, and much of today’s existing workforce is closing in on retirement. Add to this that there are fewer workers who are comfortable working at heights and need experience and special qualifications or certification.

While Scaling Solutions is trying to tackle this problem on a national level by establishing a special training and certification centre in Nottingham, UK, there are things you can do as a contractor and/or a small business owner to help with the shortage of good workers. Look at a continual mentoring and education or training process in your business. Give your teams of workers the stimulation and knowledge they need to remain inspired, dedicated and proactive on site.

Don’t try to get away with minimum rates and always squeeze the workers to save a few pounds. Recruit smarter, pay better and lay out a career path for them rather than a dead end job.

Failing that… call Scaling Solutions and we provide all of that for you from first sod to project handover.

Clients and contractors try their best to accurately estimate the costs of construction projects however, the result is rarely correct and often does not allow enough leeway for the unexpected and the unforeseen.

Contracting the services of an experienced construction estimator can help to minimise unexpected costs, but also by listing every possible cause of delays or increased costs and adjusting your budget accordingly will definitely help for when these costs do unexpectedly appear.

There may be greater likelihood of certain delays or issues in a particular geographic location due to weather, ground issues, or with a specific type of project during different seasons, regulatory barriers or other factors that an experienced local estimator may be able to advise you on.

Poor communication

One of the key causes of lost time and money is a lack of clear communication between clients and project leaders and between project leaders and workers. Like all core assets on site, it must be carefully planned. Regular meetings with your employees or colleagues can help reduce unwanted miscommunication and improve productivity.

Get the whole team around the whiteboard and explain the current status and pending targets, issues or potential obstacles and get their buy-in to the proposed solution.

Help all workers on site to see the group vision and the anticipated project outcome. Encourage all workers to be aware of what could cause delays and give warning if they see anything that should be discussed or actioned. Teams play together.

Workplace health and safety

Knowledge, practices and planning for accidents and injury prevention is much more important than it once was, especially in commercial construction.

Accidents can get your site shut down for days or even weeks while a myriad of investigations are carried out with the worst outcomes being very, very expensive fines. In the UK, accident related fines are common of up to £20,000 however where there are serious acts of negligence, the fines and costs of delays can be expected to reach unlimited amounts.

Thorough training and the best protective equipment are a very small investment to avoid accidents occurring, or at least, to minimise the fallout from an accident onsite.

All workers need to be trained, the training needs to be reinforced regularly and project leaders must take an active part in the enforcement of the best health & safety practices.

Budgetary Boo Boos

Clients and contractors try their best to accurately estimate the costs of construction projects however, the result is rarely correct and often does not allow enough leeway for the unexpected and the unforeseen.

Contracting the services of an experienced construction estimator can help to minimise unexpected costs, but also by listing every possible cause of delays or increased costs and adjusting your budget accordingly will definitely help for when these costs do unexpectedly appear.

There may be greater likelihood of certain delays or issues in a particular geographic location due to weather, ground issues, or with a specific type of project during different seasons, regulatory barriers or other factors that an experienced local estimator may be able to advise you on.

Lack of responsibility

Taking ownership of work to be done means taking the accolades when it is done well and the responsibility for a botched outcome. Responsibility must permeate every level of the work site and every worker active on the site. They must know how the outcome of their actions will effect the performance of the next person and indeed, the entire project outcome.

There is no doubt that everybody makes mistakes, what is not always clear is why some people make them more often than others. To minimise poor task outcomes, it is essential for contractors to honestly evaluate their skillset and any limitations before commencing any project and it is vital that project managers thoroughly check the experience and capabilities of their sub-contractors or employees.

Project (mis) Managers

It is laughable but true that some people serving as site managers are appointed to this role with very little prior experience. Often these hapless individuals could not even begin to dream of the issues that would arise as a direct result of their inexperience. Nor can they understand the great responsibility that has been tasked to them. You will spot them easily as they spend their days avoiding decisions, passing them off to others or hiding in their office watching YouTube and praying that the day is reasonably uneventful. They will very rarely be where they are needed most, out on site.

Managing a construction project is not easy and carries a lot of pressure on a minute by minute basis. Everything that occurs on the site, or should occur on the site, or did not occur on the site, or needs to be changed on the site has to filter through the site leader’s consciousness to become enriched from his/her experience, knowledge or researched solution.

Project mismanagement can be caused by anything from making rough guesstimates, lazy assumptions or hopeful expectations, simple miscalculations, over confidence in the skills and enthusiasm of the workers, lack of forward thinking to ensure the components, tools, labour requirements or work areas are prepared and operational, often due to a lack of experience. A poorly managed construction site can cause major problems for the project owners and can impact day to day productivity, health and safety and the final outcome. The experienced and dedicated PM will be ever vigilant, ensure clear and continuous communications, plan ahead for every eventuality and keep the client fully updated with changes in planning and special requirements.

Lack of Planning

Planning will help many of the issues that are listed in today’s post to be avoided or soon overcome. Planning is the key to success with every construction project. The statistic of 90% of construction projects experiencing delays would be far lower with more sites having much more thorough planning in place.

Great project management takes into account the domino effect. If one negative event happens, how will that lead to other negative effects which will themselves cause further negative effects. The great PM is a chess master, planning every move to bring the project closer to fulfilment with a minimum of losses or delays.

Scheduling can be tricky for even the most seasoned project manager. Modern evolving construction technology is providing a solution for this common problem. Look into the various project management apps that you can access from your desktop or your smartphone which allow you to visually map out a project timeline. Many apps allow for a “sticky-note” style virtual board that allows you to easily see what is planned ahead, and gives real-time project status updates.

Without detailed planning and leadership, it is likely that the progression and organization of the project will eventually become a complete mess. Great planning must be communicated clearly to everyone up and down the chain of responsibility.

If weather or missing components or other delays stop the installers from climbing… have a plan B where their time is well utilised else where such as ground assembly or protocols or other useful activities.

Unrealistic expectations

Whether these are the expectations of the client, the project manager, contractors, employees or suppliers, being unrealistic about any part of the process or outcome can turn a smoothly running project into a complete disaster. Such false expectations are most often a result of inexperience in the managers or workers, or management relying upon very poor advice.

Test all assumptions, call for experienced advice… still unsure? Get second or third opinions because unrealistic expectations are the cornerstone of failure or dissatisfaction.

Then, communicate the heck out of any unrealistic expectations so that everyone from the client to the workers have their reality checked and their expectations re-aligned.

There are a myriad of things that can and will go completely wrong on a construction project without sufficient planning and experienced management.

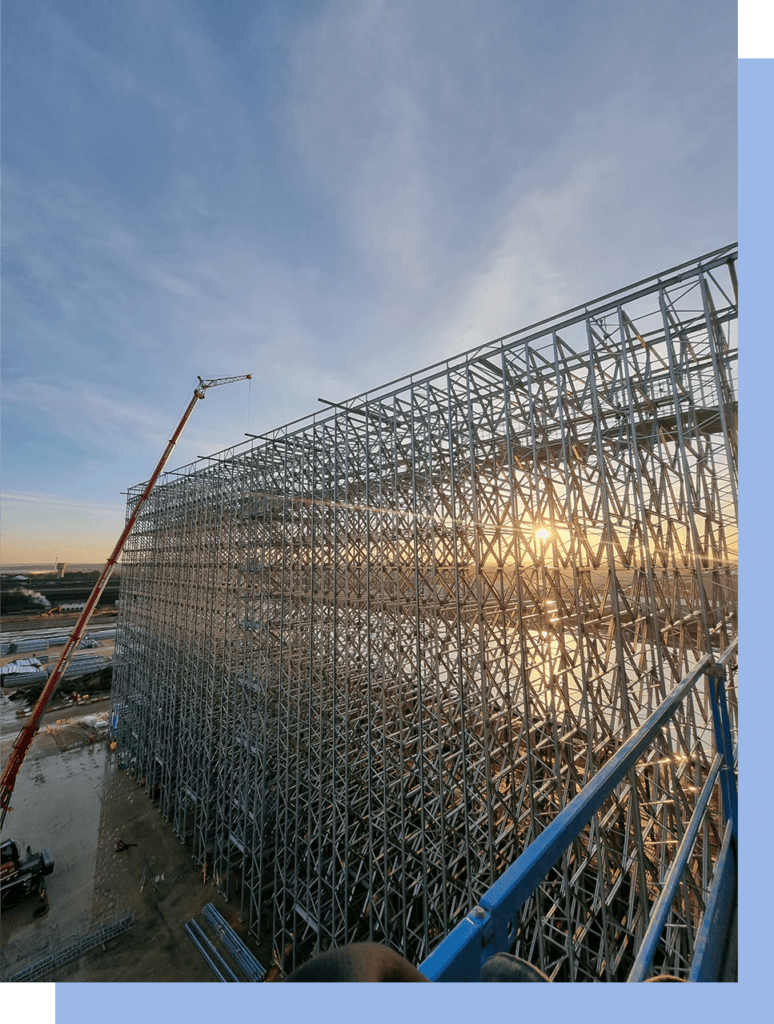

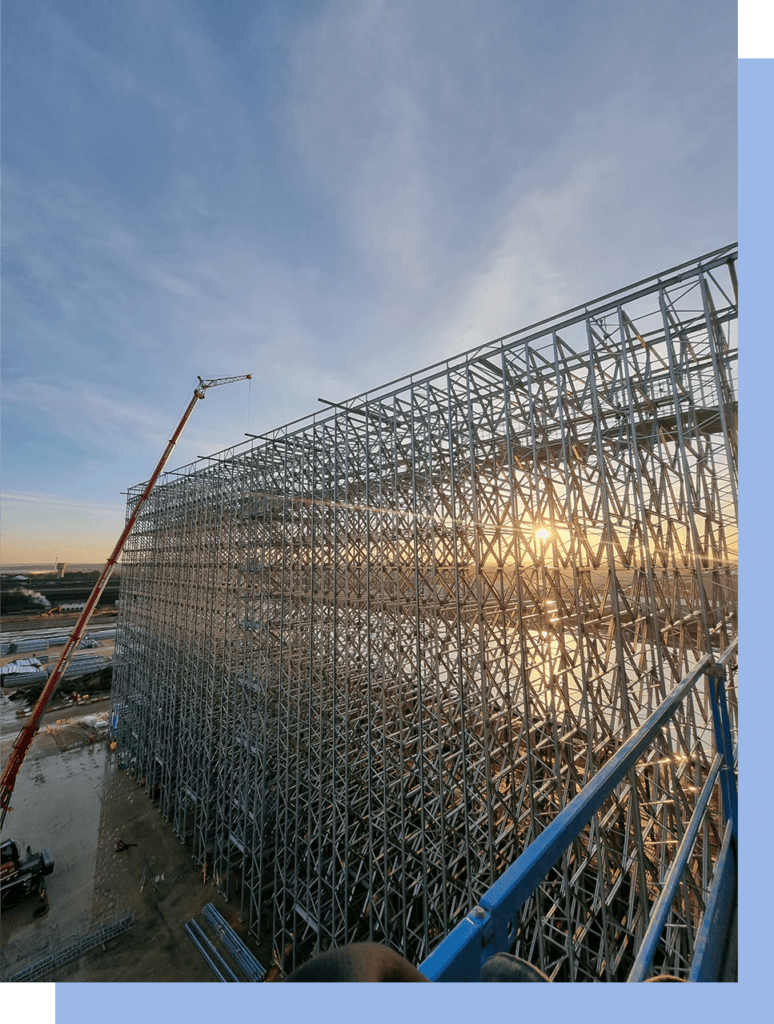

Scaling Solutions teams have decades of experience and have built some of the largest clad rack logistics centres in Europe. We have also been called in to help to fix some projects that have gone completely off the rails and were heading toward disaster and massive penalties.

There is one core issue that undermines the integrity and momentum of big logistics warehousing projects and that is a lack of INTEGRATION. The entire project should operate as a mesh, not a pyramid. Every person’s activities should be seamlessly connected to the clearly communicated vision for the project’s outcome.

To achieve this end, Scaling Solutions train our own teams in our own purpose built training facility in Nottinghamshire, to function like an army, fully integrated with the project and our client’s outcomes. We provide and manage all personnel on site, on the ground and in the air, with clear reporting channels and responsibilities.

Our project managers and site managers have many years of dedicated experience and specialty training to ensure they are highly certified and totally prepared for every project undertaken.

Our teams participate in daily briefings and are rewarded for meeting and exceeding team objectives.

We recently broke SSL-Schaefer’s world record for installation speed and quality.

Our client’s budget and schedule are fully integrated within our planning process so that our outcomes are identical to theirs. We have zero unrealistic expectations as these have been reappraised, communicated and rationalised back to reliable and achievable objectives.

Our managers are out and about the site calibrating activities continuously, not hunkered down in a cabin watching YouTube.

We live your project, we share your vision and we bring it to life.